Why You NEVER Want a Puncture

And How it's Expensive and Dangerous

A truck driver in the Free State was stabbed to death on the N11 after he stopped to change a flat tyre.

A police spokesperson said the driver was unscrewing the wheel bolts when a group of men armed with sharp objected attacked him. The attacker took his shoes, glasses and the truck keys, leaving him for dead.

Changing a tyre is rated as an annoyance but annual road safety statistics prove motorists are robbed and assaulted at gunpoint regularly.

We are certain that you will agree that there are many roads in our country that we would prefer not to get out of our vehicle at all due to possible danger to our lives, let alone change a tyre in an exposed position.

If you decide to sit tight in your vehicle and wait for help, it still remains a scary scenario and you are still at high risk.

Even if it’s broad daylight and you feel safe enough to attempt changing the tyre, the risks don’t stop there. Few statistics show how many people are injured while changing a tyre, but many emergency experts tell horror stories of motorists, police officers and good Samaritans being killed or injured while attempting to change a flat.

Then there are the questions of capability and achievability: can you physically do the job, and do you have all the right “tools?” Is your spare properly inflated? Can you remove the wheel nuts and raise the vehicle with the jack? Is the jack and wheel spanner in place? Have you done this before… on your own?

It’s a daunting and dirty job in the best circumstances, and that’s not taking into account the expensive downtime when you’re mining vehicles are not doing its job, which would equate to millions in profits lost.

Expensive DOWNTIME

And How It Can Cost You Millions

We all know that Downtime in Mining is more expensive than in any other industry.

When it comes to Mining, downtime can cost millions of Rands in a single shift.

A mining dump truck’s downtime is estimated by equipment maker Cummins to cost up to USD $1000 per hour, while an excavator is considerably more expensive.

This is not even taking into account the penalties from breached Service Level Agreements.

Therefore, downtime is a concern that needs special attention, and we collaborate closely with our mining customers to prevent tyre punctures and loss of productivity and revenue.

Pressure is Your Enemy

The Problem You Didn't Know You Have

You have a huge pressure problem (without knowing it) and it’s adding huge risk and costs to your life.

Your vehicle is held up by a few pieces of tyre rubber totaling only the size of an A4 scrap of paper… carrying you and your precious cargo.

Manufacturers create each tyre model to be operated at exactly the right amount of air pressure. Without adhering to the right pressure, you put yourself and your precious cargo at risk.

Unfortunately, unless you are putting in a LOT of energy checking tyre pressure and being aware of various technical issues you will likely never get it right:

Here’s Why You Cannot Get It Right on Your Own:

- Motorists do not check their tyre pressure regularly enough and many do not know the correct amount

- Tyre rubber is porous (worse with age) which allows the air molecules to naturally escape right through the rubber

- Even with a TPMS, the low-pressure alert only happens when your tyre is 25% below the correct pressure

- Checking tyre pressure during a fuel stop is not advised as tyre air shrinks and expands as it heats and cools providing the incorrect inflation in hot tyres

- An undetectable slow puncture will be losing air the moment you leave an air filling station

Pressure Destroys Your Fuel and Tyre Economy

It's not Only Dangerous but Expensive

Wasting Fuel?

Unless you are using Armour Tyre Sealant your tyres are likely to be underinflated due to slow punctures, porous rubber, leaking valves, rim leaks, checking pressure at the wrong time (hot tyres) and insufficient maintenance.

Remember how difficult it was to peddle a bicycle with flat tyres? You had to work harder (you experienced high rolling resistance) and yet once the tyres were inflated you could glide along effortlessly.

Your engine has to work harder to move a vehicle with one or more underinflated tyres. When your engine works harder it uses a lot more fuel and wears tyres faster and unevenly.

Wearing Down Your Tyres?

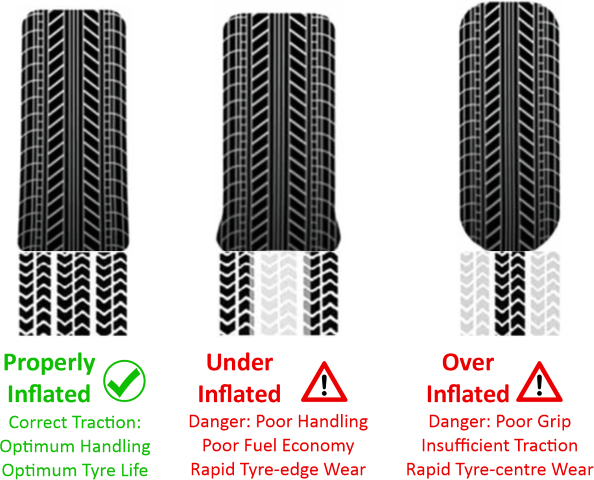

Tyres are similar to balloons with their shape deforming as pressure and weight are exerted. If your tyre’s air pressure is incorrect then the shape of the tyre is incorrectly deformed as in the image affecting your tyre wear and your safety.

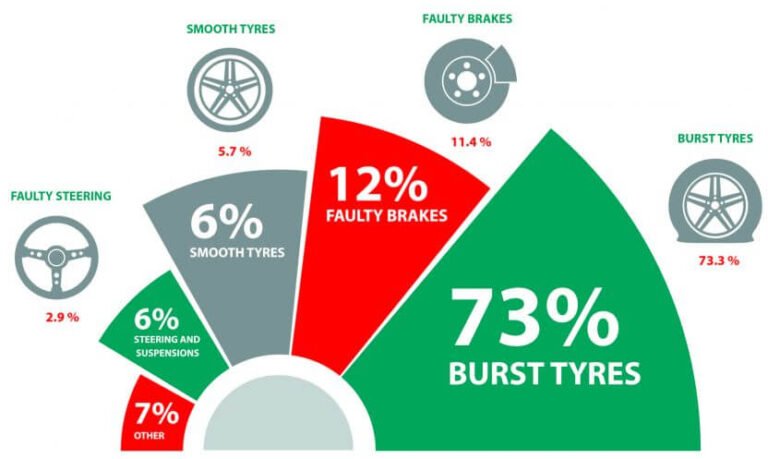

Up to 73% of accidents in South Africa are tyre-related, causing blow-outs and as many as 45% of taller vehicles, such as your Side Tippers will roll resulting in many casualties.

Having Armour Sealant in your tyres will regulate your tyre pressure for the life of the tyre, and eliminate punctures on the fly while letting you enjoy the benefits of saving fuel and tyres, and the peace of mind by knowing you won’t be on the side of a dangerous road trying to change a tyre due to a puncture.

How it Works

Install and Forget but Remain Protected

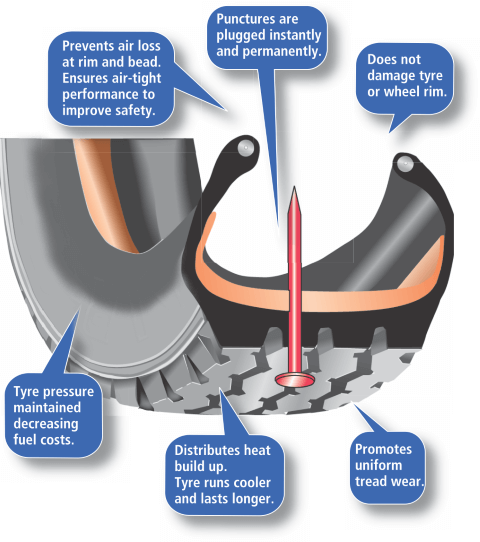

Our premium sealant is inserted into the tyre and remains there for the life of the tyre providing you with our amazing pressure regulating benefits.

The core proprietary liquid suspension, which contains food-safe ingredients, is spread by centrifugal spinning forces to the tread section of the inner-tyre. Suspended in the liquid are micro-granules, fillers and aramid fibres (this is what stops bullets in a bullet-proof vest – and also stops punctures in our solution) that are carried to the site of any air escaping from the tyre.

As the liquid escapes from the leaking point in the tyre, an electro-chemical process helps create and build a dam (like a beaver) of micro-granules, fillers and aramid fibres creating a “bullet-proof” permanent airtight plug.

Our Clients Loving the Peace of Mind

Increasing Tyre Life Without Downtime

How to Install?

Easy Installation

In this video, we will show you how to Assemble and Maintain the manual pump and how to Install into a Tyre.

Who's it For?

What Type of Vehicles and What Quantity

If you own anything with wheels, this is for YOU!

Fast Moving Vehicles

Vehicle tyres that may exceed 80km/h must be pre-balanced and one should insert exactly the same amount per tyre and not exceed the recommendations.

Slow Moving Vehicles

If your vehicle is “slow-moving” below 80km/h then you can elect to apply more sealant if entering puncture-prone environments.

Off-Road Vehicles

Vehicles that frequent “off-road” will likely frequent puncture-prone environments and could apply more sealant.

For any unusual applications reach out to us for free advice.

Vehicle Description and Volumes

Sealant volumes required are determined by the size of the tyre and where it will be used with estimated amounts listed here per group of vehicles.

Yes! It will even work in the lowly wheelbarrow. Wheelbarrow tyres live in the garden or on site and become sun baked and damaged, cracking and becoming porous leaking their air.

250ml is sufficient for all standard wheelbarrows although as a slow moving vehicle it can take up to double in puncture-prone areas.

Who needs the headache of a puncture while you’re enjoying your ride in the mountain or out on the road?

125ml required per tyre for your road bike

175ml required per tyre for your mountain bike

250ml required per tyre for super-size mountain bikes

Your All-Terrain Vehicle is always driving in gnarly off-road conditions and you’re usually very far from home when you sustain a puncture. And that goes for when you’re out on the green with your golfclubs or enjoying your quad. Why take the unnecessary risk?

1000ml – 1750ml depending on your tyre sizes.

As there are many variations of tyre types please check your tyre size against our Tyre Chart

Motorcycles don’t come with a spare tyre, so why risk yourself, your bike, and the enjoyment of your ride by unnecessarily sustaining a puncture.

125ml – 250ml for your motorcycle depending on your tyre sizes.

As there are many variations of tyre types please check your tyre size against our Tyre Chart

Most people commute to work, home, the store, to friends and other various outings every day, so why not give more thought to the Four tyres between you and the road, that are carrying you to those places?

250ml – 375ml needed depending on your tyre sizes

As there are many variations of tyre types please check your tyre size against our Tyre Chart

Your bakkie or Van is most probably your work horse and is driving all day long. Why put your driver and cargo at risk from a puncture?

375ml – 500ml needed depending on your tyre sizes

As there are many variations of tyre types please check your tyre size against our Tyre Chart

A happy client of ours had to take an extra 3 spare tyres on their 4×4 trips as punctures were always a problem. Now they don’t take any and enjoy the extra space and peace of mind Armour Tyre Sealant gives them.

500ml – 750ml for off-road conditions depending on your tyre sizes.

As there are many variations of tyre types please check your tyre size against our Tyre Chart

Don’t go on those long trips without protecting your trailer tyres against punctures!

250ml – 500ml needed depending on your tyre sizes

As there are many variations of tyre types please check your tyre size against our Tyre Chart

Commercial industries rely greatly on their tyres and understand the importance to their profitability and successful operations.

We supply Fleets/Road Haulage Industry, Waste Management, Mining, Agriculture, Engineering, Tour Operators, Buses etc. to help them eliminate and offset transportation pain point costs.

Commercial clients are often able to offset the cost of the sealant and still achieve massive additional savings to their bottom line due to their aggressive working conditions and high mileage.

Savings of even a few percent on annual fuel and tyre expenses alone will be an attractive and irresistible offering while also providing safety to your fleets by eliminating punctures and roadside downtime.

We have reserved strong and attractive volume-based discounts and would like to facilitate a free costing process for you to evaluate.

Please contact us directly for assistance at Info@ArmourSealant.com or call +27 87 997 0 997

Our Guarantee To You: Armour Tyre Sealant will not separate or harden, is water-soluble, safe for you and for the environment, with no shelf-life and will last the life of your Tyre. It will seal punctures up to 15mm in size, and up to 95% in Tubeless Tyres and 75% in Tubed Tyres.

Frequently Asked Questions

Yes.

It will form a permanent plug.

Yes.

In respect of full disclosure, vehicles that have tyres that are not fully balanced or incorrectly balanced may result in a small vibration at certain speeds (above 80km/h) due to adding sealant to the tyres.

Vibration in a vehicle can be caused by a number of things such as bad shocks, loose control arms, worn tie rods and bad wheel bearings and abnormal tire wear (cupping, scalloping, feathering) from an out-of-alignment or damaged suspension system.

After installation, you might assume the sealant caused the vibration but it may have simply been made more noticeable by one of the above conditions.

For many customers, this is not a deterrent, as they believe that the benefits of eliminating punctures, alongside a dangerous road, improving fuel consumption and extending tyre life far outweigh the possibility of a little vibration at certain speeds (not always).

It’s also VERY important that you put the exact same amount of sealant in all four tyres to reduce the risk of vibration.

Let’s break this down so you can evaluate and make a decision if you value these benefits:

Motorists who find they get a small vibration window between, let’s say 120 and 125 km/h and disappear thereafter (typically higher speeds beyond 80 km/h) simply don’t travel consistently at those speeds (with or without sealant.)

As our one of our loyal return customers says, “Yes, I get a little vibration at certain speeds, so I just don’t cruise at those speeds!”

Yes.

Armour Tyre Sealant prevents leaks and pressure loss. A pressure drop of just 0.5 Bar (0.05 MPa, 7.3 PSI) increases rolling resistance by 15%, which determines an increase of fuel consumption in the range of 2-5% in vehicles.

All vehicles with tyres on a surface experience rolling resistance which is the combined friction force that holds back a vehicle from moving forward. Your engine consumes energy and fuel to overcome this friction and move you forward. Underinflated tyres have a deformed profile and therefore create additional friction on the road surface that causes the engine to work harder and consume more energy or fuel. The deformed shape also rapidly wears the tyre unevenly losing as much as 30% of your tyre life.

No.

A special rust inhibitor is added to our sealant which will actually protect your rims from rusting.

Yes.

Install Armour Sealant into the punctured tyre, reinflate, then drive a few metres so the sealant can get to the punctured hole to permanently seal it. You might need to top up your air after.

Yes.

Only 19% of consumers properly check and inflate their tyres, according to the National High Traffic Safety Administration. Consequently, one in four (25%) cars has a tyre that is significantly underinflated, says the agency. This not only means heat can build up in the tyre, risking failure and additional tyre wear, but underinflation can hurt fuel economy.

We applaud you if you are checking tyre pressures but unfortunately, there is an error-prone exercise:

- Many motorists check their tyre pressure while filling up for fuel which likely means their tyres are hot and air expands meaning your tyres now have the incorrect tyre pressure. Just 10 degrees Celsius change translates to 0.345 bar pressure loss. It is very inconvenient to check tyre pressure early and before you have driven while your tyres are cold.

- In our survey of air filling devices at petrol stations, we found that tyre gauges are poorly maintained and handled resulting in uncalibrated and incorrect amounts between each air pump. Again, this means your good efforts are wasted.

- Many motorists confirm that when checking their tyre pressure they will find that one or more tyres will be out even if checked recently. This logically means that some of your tyres are losing pressure faster than others. This likely means a slow puncture in the tread wall, a rim leak or a faulty valve. The moment you drive out of the filling station you are already running underinflated costing you.

Installing Armour Sealant means that you can confirm the ideal pressure and seal the air leaks all at the optimum temperature and then just provide checkups when you can. All the “pressure” is off you while ensuring you keep running costs down.

Yes for Indirect TPMS and maybe for Direct TPMS.

You will need to identify what you have and what your objective is.

Most owners of TPMS have them because they are mandatory in some countries due to the TREAD Act or because they heard it was a great idea to make sure they never get a puncture.

A TPMS (Tyre Pressure Monitoring System) reports back to the driver if their tyre pressure is low. Unfortunately, the design is a bit questionable as the majority of TPMS only notifies the driver when the tyre pressure drops below 25% of the recommended inflation. We do NOT agree with a strategy that allows you to drive with up to four tyres that might be 24% below recommended pressure – it’s a false security blanket and a high risk of a potential accident.

Additionally, many customers report that their TPMS provides false reports due to temperature changes or when calibration is off. This also occurs when the batteries go flat and replacing them is an expensive process as some require new TPMS as the batteries are hard-mouled into the device. New dealer TPMS may cost anywhere from R1000 ($60) upwards per sensor.

Some of our customers, that had incompatible TPMS, have felt that their TPMS was not providing the original reason for them in the first place – to eliminate the risk of punctures – which it does not and rather had them removed and replaced with normal valves and rather relied on our sealants. It’s your call but know the facts.

This is why more than ever you need additional backup in the form of Armour Tyre Sealant.

Unfortunately, TPMS means you may have to do some workarounds:

There are TWO main categories of TPMS:

Indirect TPMS

These systems work by using the vehicle’s Antilock Braking System (ABS). The ABS monitors the wheel speed and it reports any variation back to an indicator inside the driver’s cabin.

Installation:

This TPMS type does not need additional devices to be mounted on the wheels as it works with the ABS monitor. So the tyre valve is standard and you can still install the tyre sealant with the standard procedure.

Direct TPMS

These systems are the most common with the sensors mounted onto the rims. Many designs actually replace the air valve housing with the TPMS unit which has an electronic transmitter inside that measure the air pressure and communicates to a panel or receiver inside the driver’s cabin.

When inflating the tyre or adding sealant through the valve stem with some indirect TPMS the sealant now has to go through the TPMS housing. The channel is smaller and the sealant may block the TPMS.

Installation:

To install the sealant please visit a tyre fitment centre that can deflate your tyre and insert the sealant directly into the tyre via the rim and bead.

Armour Tyre Sealant will last the legal life of the tyre, has no shelf life and will not harden or separate in a sealed container.

Yes!

Different tyre sizes need different amounts of sealant. Bigger tyres will obviously need more sealant than smaller tyres. Armour Tyre Sealant needs to spread evenly on the inside of the tyre in order to work effectively.

It’s also important that you put exactly the same amount of sealant in all four tyres to reduce the risk of vibration.

No.

Unless you have a slow-moving vehicle such as a tractor never accept advice that offers to repair sidewall damage.

Sidewall damage affects the structural integrity of the tyre and if repaired it could experience a blowout at high speed involving you in a life-threatening situation.

Tyre manufacturers suggest replacing a tyre with sidewall damage for your own safety so it’s best to visit an approved tyre repair workshop and have them assess the tyre for structural integrity.

Also, the sealant needs to be able to reach the puncture wound in order to seal it and that may not be the case on sidewalls.

We have had reports of clients in an emergency removing the tyre, laying it on its side and allowing the sealant to reach the sidewall in order to provide an emergency plug that could get them, at a slow speed, to a repair shop and safety.

Tyres typically lose up to 2% of their air pressure every month through the porosity of the tyre and much more if there is a slow leak. A tyre that is underinflated by 20% can exhibit irregular wear and reduce tyre life by up to 30%.

Mismatches between identical tyres can be caused by differences in air pressure. Variances as small as 0.34 Bar (5 psi) can cause the tires to be mismatched. This type of mismatch can occur even when the tyre make, model, tread depth and diameter are identical.

Yes.

There’s no problem using nitrogen and Armour Sealant together. Installation is the same. Deflate tyre partially, then reinflate with nitrogen (if you are so inclined).

Yes, it’s ideal as it saves you more.

Run flats are designed to allow you to drive for up to 80 kilometres at 80 km/h after getting a flat. Many report that they chose run-flats to offset the threat of punctures or that they came with a new car. As they are 50 to 200% more expensive than regular tyres. Once you have a run flat puncture it typically ruins the tyre and it needs to be replaced turning a mere puncture into a very expensive event. Installing Armour Sealant works collaboratively with your run flats but prevents you from having a puncture in the first place and therefore protects your expensive investment for when you really need them.